Delivering High Chrome Casting, Concave Mantle Casting, Jaw Crusher Plate, etc. for various industrial solutions.

HOT PRODUCTS

About Us

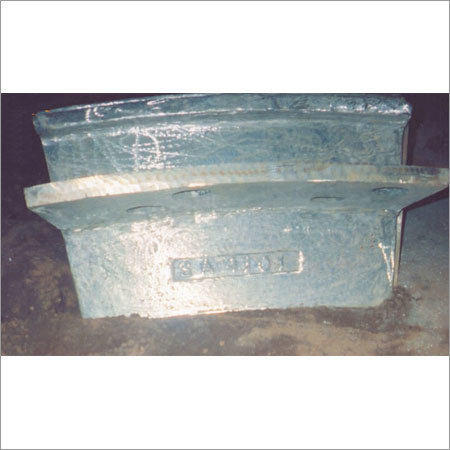

Understanding the need of steel casting and industrial tools in the industry, we, Model Steel Casting, a Bellary, Karnataka based manufacturer, are making available proactive and innovative range of products that have excellent operational efficiency. Our Jaw Crusher Plate, Concave Mantle Casting, Mining Mantel Casting, Stainless Steel Casting, Concave Mantle Casting, High Chrome Casting, Cone Crusher Mantles, and other products are in superior quality. Since we use A-one rated materials, our range offers great abrasion resistance, appears seamless and are tough in strength. In industries such as Mineral Processing, Cement, Steel, Paper, and many others, our offered line finds great use. As manufacturer, we lay complete focus over quality making as a result of which we have now become a dependable name in the Indian Industry. Our focus towards research and innovation has also boosted our demand in the market. In addition to engineering perfection, we have also implemented premium quality management policies that guides us in creating only excellence for our clients.

- Cement- Supporting Rollers, Hammers, Kiln, Liners, Tip Casting, Cooler Plates, etc.

- Steel- Bowl Liner, Lower Mantle, Apron Pan, etc.

- Thermal Power Plant- Lower Skit Assembly, Liners, Bull Ring Segments, etc.

- Engineering- Nihard Casting, Cast Steel, etc.

- Mining- Tooth Points, Shivel Teeth, etc.

- Stone Crusher- Concave, Swing Jaw Plates, etc.

|

Cement |

Cooler Grate Plates, GR Media Balls, Raw Mill Liners, Cement Mill, Hammer, etc. |

|

Power Plants |

Burner Diffuser, Ash Handling Pipes, Nihard Liners, Ring Hammers, Tube Supports, Impellers, Pelton Runners, Bull Ring Segments, Impeller, etc. |

|

Heat Treating |

Damper, Roller Rails, Boxes, Baskets, Fixtures,

Skid Rails, Radiant Tubes, Retorts, etc. |

|

Steel Plants |

Conveyor Parts, End Seals For Soaking Pit, Grate Bars, Apron

Pans, Baffles, Radiant Tubes, Retorts, Blow Pipes, Furnace Skids,

Furnace Doors & Frames, etc. |

|

Chemical |

Pump and Valve Parts, Liners, Burner Parts, Grinders Mixtures, Nozzles,etc. |

|

Aeronautical |

After Burner Parts, Engine Supports, Jet Engine Rotors,etc. |

|

Pulp & Paper |

Pump Parts, Disc Refiners, Conical Refiners, etc. |

|

Metal, Mining, Smelting and Refining |

Concaves, Retorts, Dampers, Bowl and Mantel Liners, Pipe Fittings, Tooth point, etc. |

|

Marine |

Marine Hardware, Propeller- Shaft Bearings, Valve Part, etc. |

Download Brochure